Stop guessing your cows’ cycles and kiss tail paint and kamars goodbye. All you need to never miss a heat are ear sensors. Ear sensors that measure cows’ rumination, eating, inactivity, activity, high active behaviour, and ear temperature. And those happen to be the perfect parameters to determine heat intensity and heat stage, and much more.

Kissing Tail Paint and Kamars Goodbye

With CowManager ear sensors, you’ll know exactly when to inseminate. The system will tell you exactly which cow is in heat, sending you an alert to your computer as well as your smartphone. Cows coming into heat show up as light blue in the system, moving to light green as the heat progresses. Finally, they turn dark green when they are fully on heat. One look at your phone or pc, and you’ve got all the data about heat intensity and heat stage of each individual cow. Heat peaks, possible pregnancies, non-cycling cows and even potential abortions.

For Peter and Alyse Slade (pictured above), this was a gamechanger.

“CowManager went in two weeks before mating last season. Our first mindset was that tail painting was still going to be our main heat detection and that CowManager was our backup. Four days in and tail paint was gone, and we’re now 100% relying on CowManager for all our heat detection. We got an increase in our 6 week in-calf rate, which was pretty unreal.”

As Easy as Getting a Text

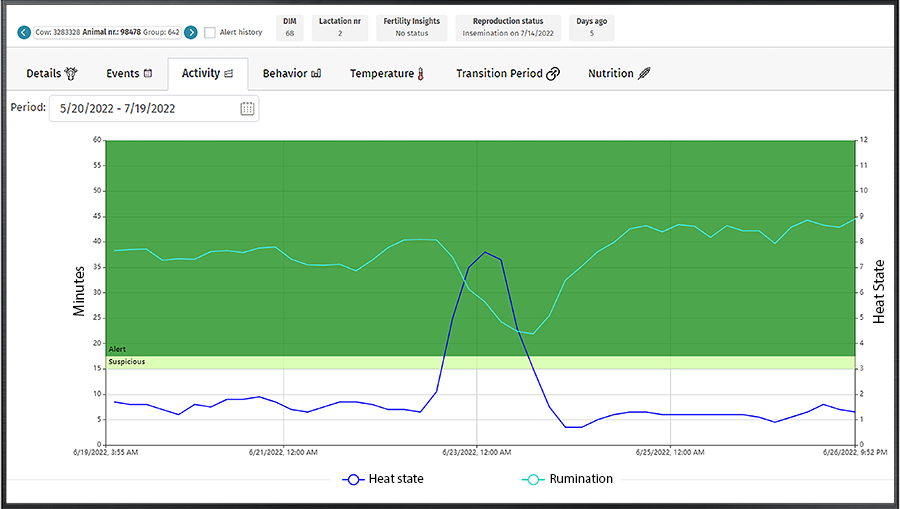

CowManager shares alerts like ‘Potential’, ‘Suspicious’ and ‘In Heat’. By clicking on the specific alert, you can view the activity graph of an individual cow helping you determine the optimal breeding. After receiving a heat alert, inseminating 10 to 22 hours after it is the most ideal. Of course, the system calculates and refreshes all alerts every hour.

One of the fertility graphs in the CowManager system.

Kaylene and Bill Aubrey had an empty rate in their three-year-old cows of 2% last year. The rest of the herd has been between 6% and 9% for the past two seasons. They wouldn’t have had these results without using the ear sensor technology for heat detection.

“We wouldn’t be without it and have a lot of people come and look at the system”, Bill says.

Improving Fertility Numbers

Ethan and Jaime artificially inseminate all the way through. CowManager has reduced stress over mating periods and allowed them to confidently utilise more expensive genetics in their herd due to the accuracy of CowManager heat detection. They achieved an MT rate of 6.9% across all their stock on the farm, including yearlings for their 10 weeks of AB (6 weeks Holstein Friesian and 4 weeks Short Gestation Belgian Blue).

“Before installing CowManager we used tail-paint, scratchies, and eye work. Now we simply turn up to the shed and all the cows in heat are right there for us ready to be mated.”

Mike Marshall agrees: “It’s great. We’ve increased our six week in-calf-rate by about 15%, so we’ve gone up to 78% in our six week in-calf-rate. Our empty rate has dropped from about 24% down to 13%. It’s quite substantial. We’re also picking up those silent heats that we weren’t able to pick up beforehand.”

So far, CowManager has averaged an 8% increase in New Zealand farms’ six-week in-calf rate and a 5% decrease in their empty rate. Most of those farmers no longer use bulls, are breeding more replacements to keep or sell, often via sexed semen, and putting fewer or no bobbies on the truck.

Better for the Herd, Better for Home

For some, using the system adds an extra layer of efficiency due to their family situation.

Jason Laurence, father to two young kids, explains: “We don’t have to worry about kamars or tail paint or any of that. Especially with our young family. I don’t have to stress about having someone look after the kids while me and my wife kamar the cows or paint them.”

Jason Laurence and his family.

Less family stress is something Paul Leslie can get on board with. His wife Keren says he used to be a religious tail painter. “I touched it up night and morning, so I was constantly jumping up and down, not focusing on the actual milking”, Paul adds.

Tail painting was slowly ruining his back, and the workload would keep him from joining in on family events. Now, their 6-week in-calf rate has gone up to 76% – and Paul’s spirits have improved as well as they’re enjoying more family time.

Paul: “In terms of heat, it’s the trust in the data. I think that’s the biggest transition in the thought process you’ve got to undertake. You have to trust the data in front of you.”

Ready To Trust the Data?

Would you like to discuss the benefits of cow monitoring with like-minded people? Get in touch with our local representatives to ask all your questions or to get a personalised quote. Check out our New Zealand web page for more information.