Everything Else

Reducing the herds SCC from a 150,000 to 70,000 is the result of excellent management, early actionable health alerts, smart culling decisions and great cow health. In 2014 Benthem Brothers original activity monitoring system was reaching the end of its lifespan. A decision had to be made to invest again or go back to how it used to be. Going back was not an option. Fortunately, there was new technology available that could also help with herd health.

Jason knew they didn’t want to change batteries or collars. Fortunately, heat detection in the form of an ear tag was available in CowManager, eliminating those hassles. But wait, there’s more. That little ear tag also monitors cow health.

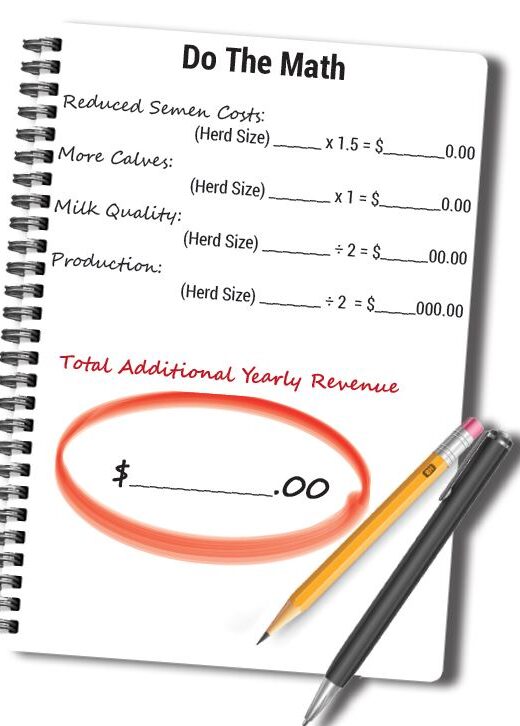

Getting cows bred on time, plus finding and treating cows sooner equals better transition. Better transition along with good bedding and good nutrition equates to lots of high-quality milk. All things you know, but what’s the real math?

Milk Quality

Improved milk quality can pay significant dividends in the form of quality bonuses. What difference would 20 cents/cwt make at the end of the year? Figure it out by dividing your herd size in half and add two zeros. That is the dollar amount accessing more quality bonuses could have for your dairy. Where you’re starting from will impact what opportunity you have, but it could be as high as 14 cents/head/day. Go ahead, do the math.

Production

The increase in milk, fat and protein starts with good reproduction, healthy cows and good nutrition. On this dairy it totaled 3,300 more pounds of milk, 72 pounds more fat and 132 pounds more protein. How much could that have helped this past year? Do your own math. Divide your herd size in half and add three zeros. Significant increases in pounds of milk and components can lead to revenue increases of $1.36/head/day.

If you’ve played along you should have some dollar figures scribbled in the column to the left. Add them up and take a minute to consider how that additional revenue might have changed things for your dairy this past year.

Admittedly the math we used was unconventional, but it was intentional. Do the math your own way and we think you’ll find that in the end we arrive at the same place, which is that electronic activity monitoring is here to stay and can have a significant impact to your bottom line.

Whether we are talking about a math exercise like this or the success of your operation, the key is deciding to start, and to be willing to try something different.

Nearly ten years ago, Jason took those steps by leveraging new technology and in doing so turned long time challenges for their dairy into a distant memory. It’s an inspiring story, what will yours be? Contact us if you would like to explore this idea further.